Materials, Free Full-Text

Por um escritor misterioso

Last updated 30 janeiro 2025

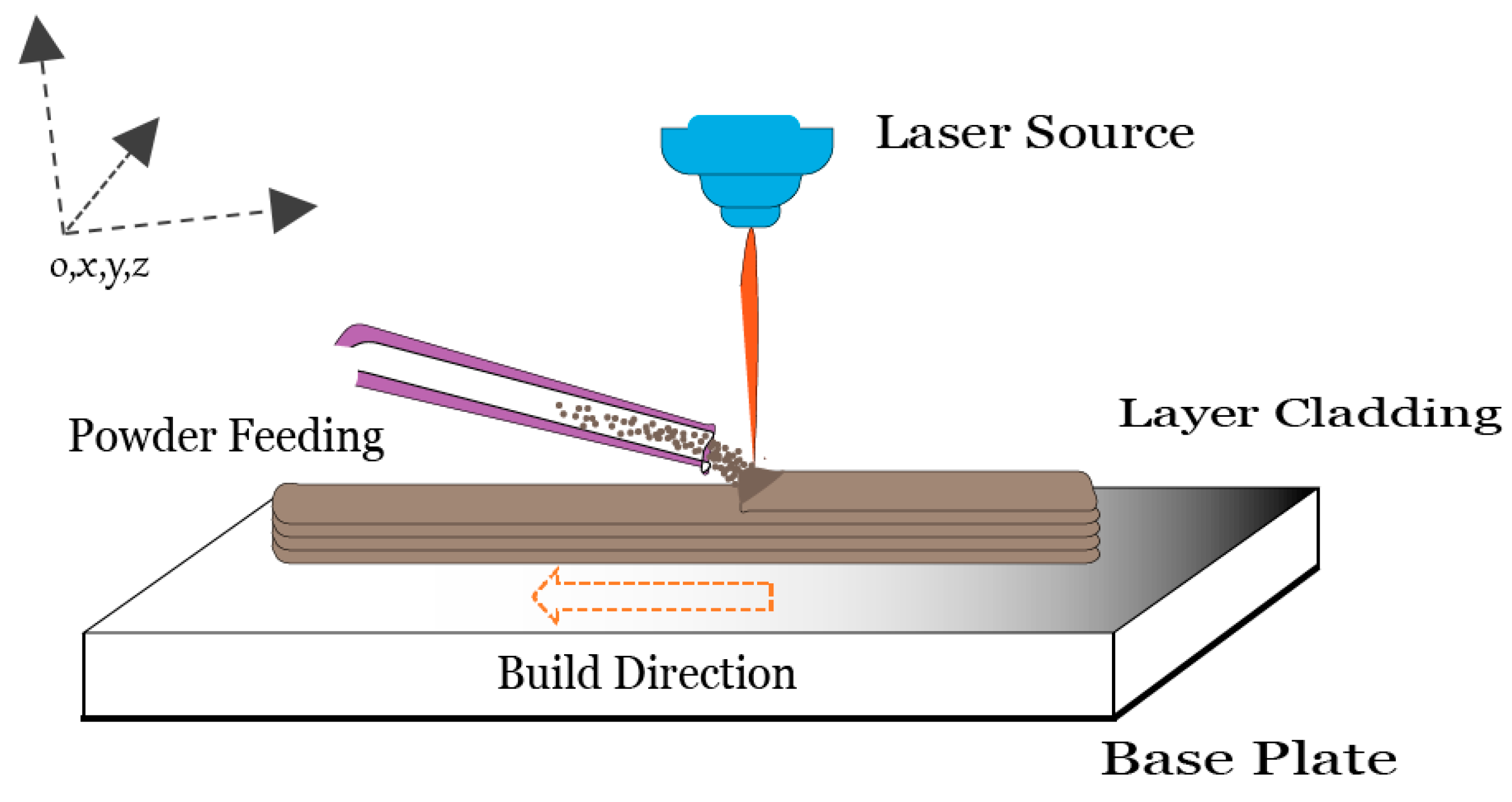

Laser cladding has emerged as a promising technique for custom-built fabrications, remanufacturing, and repair of metallic components. However, frequent melting and solidification in the process cause inevitable residual stresses that often lead to geometric discrepancies and deterioration of the end product. The accurate physical interpretation of the powder consolidation process remains challenging. Thermomechanical process simulation has the potential to comprehend the layer-by-layer additive process and subsequent part-scale implications. Nevertheless, computational accuracy and efficacy have been serious concerns so far; therefore, a hybrid FEM scheme is adopted for efficient prediction of the temperature field, residual stress, and distortion in multilayer powder-fed laser cladding of Inconel®718. A transient material deposition with powder material modeling is schematized to replicate the fabrication process. Moreover, simulation results for residual stress and distortion are verified with in-house experiments, where residual stress is measured with XRD (X-Ray Diffraction) and geometric distortion is evaluated with CMM (Coordinate Measuring Machine). A maximum tensile residual stress of 373 ± 5 MPa is found in the vicinity of the layer right in the middle of the substrate and predicted results are precisely validated with experiments. Similarly, a 0.68 ± 0.01 mm distortion is observed with numerical simulation and showed a precise agreement with experimental data for the same geometry and processing conditions. Conclusively, the implemented hybrid FEM approach demonstrated a robust and accurate prediction of transient temperature field, residual stresses, and geometric distortion in the multilayer laser cladding of Inconel®718.

Free Collection of Materials for Blender Artists

Hazardous Materials Sign Photos and Images

Journal of Materials Engineering and Performance

Journal of Materials Science: Materials in Electronics

Advanced Functional Materials: Vol 31, No 46

Materials, Free Full-Text

Materials, Free Full-Text

Transvalor Forge 2011 - Colaboratory

Tribology of carbon nanotubes - About Tribology

Materials, Free Full-Text

Materials, Free Full-Text

Materials, Free Full-Text

Materials, Free Full-Text

PDF) Materials Engineering

Recomendado para você

-

MM2 Laser Godly - Game Items - Gameflip30 janeiro 2025

-

Weapon Mm2 Laser vintage - Game Items - Gameflip30 janeiro 2025

-

Other | MM2 | Chroma Laser30 janeiro 2025

Other | MM2 | Chroma Laser30 janeiro 2025 -

laser and slasher value|TikTok Search30 janeiro 2025

-

lazer mm2 value|TikTok Search30 janeiro 2025

-

Spectre, Murder Mystery 2 Wiki30 janeiro 2025

Spectre, Murder Mystery 2 Wiki30 janeiro 2025 -

OMG! GODLY LASER GUN UNBOXING!! (Roblox Murder Mystery 2)30 janeiro 2025

OMG! GODLY LASER GUN UNBOXING!! (Roblox Murder Mystery 2)30 janeiro 2025 -

what is the value of laser in mm2|TikTok Search30 janeiro 2025

-

mm2 laser values|TikTok Search30 janeiro 2025

-

Schematic diagram of the factors affecting the ultrafast laser ablation30 janeiro 2025

Schematic diagram of the factors affecting the ultrafast laser ablation30 janeiro 2025

você pode gostar

-

IBM WebSphere MQ V5.3 Solution Development Visit: - ppt download30 janeiro 2025

IBM WebSphere MQ V5.3 Solution Development Visit: - ppt download30 janeiro 2025 -

Yokai Watch 2021 Episode 4730 janeiro 2025

Yokai Watch 2021 Episode 4730 janeiro 2025 -

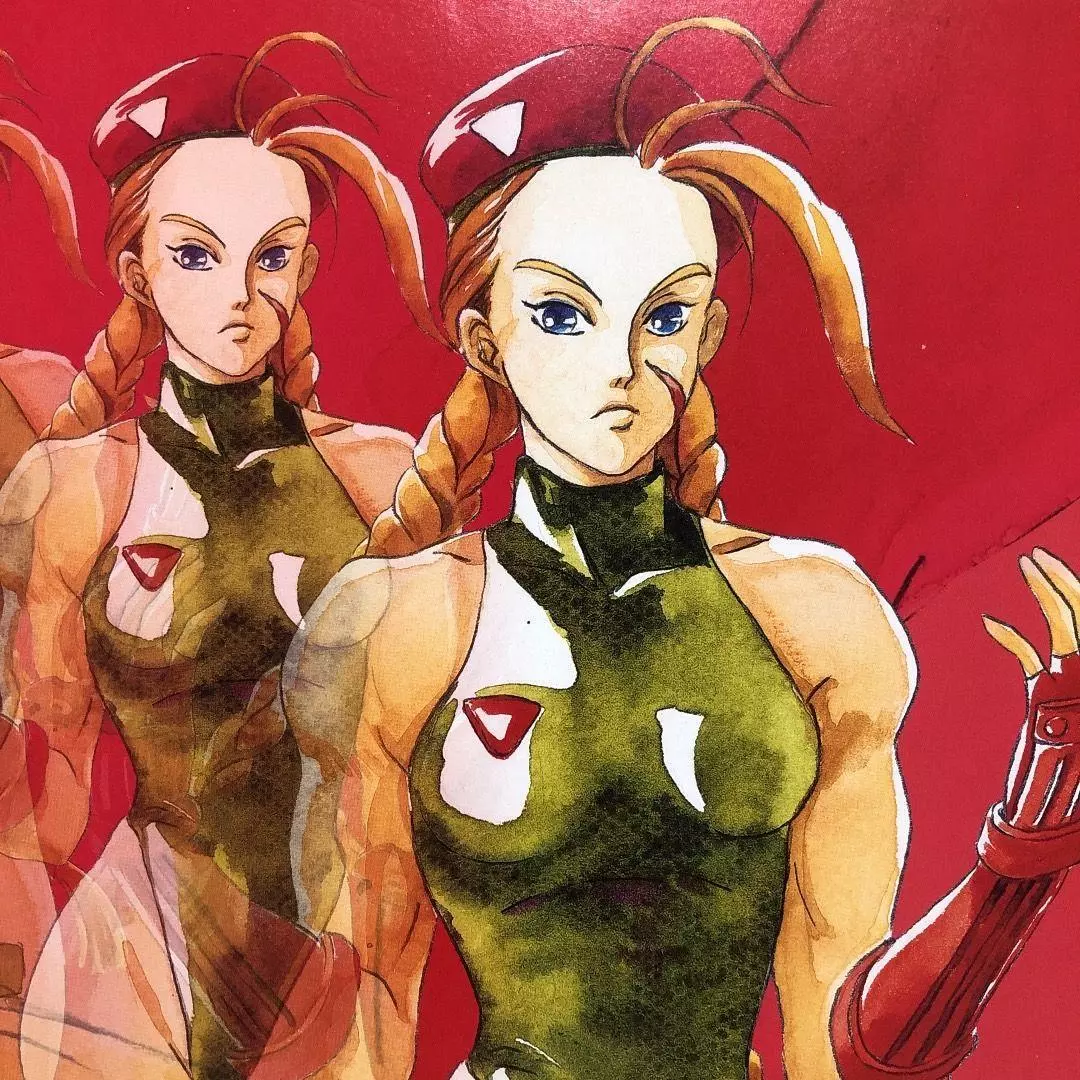

Super Rare CAPCOM Street Fighter II Poster Cammy Ver. Grand Master Challenge30 janeiro 2025

Super Rare CAPCOM Street Fighter II Poster Cammy Ver. Grand Master Challenge30 janeiro 2025 -

ArtStation - Dragonstone beach landing30 janeiro 2025

ArtStation - Dragonstone beach landing30 janeiro 2025 -

Fundo O Empresário Caindo Na Armadilha De Paraquedas Empresário30 janeiro 2025

Fundo O Empresário Caindo Na Armadilha De Paraquedas Empresário30 janeiro 2025 -

20 MEGA CÓDIGOS COM 20.000+ GEMAS NO NOVO UPDATE *ABRIL 2023* DO30 janeiro 2025

20 MEGA CÓDIGOS COM 20.000+ GEMAS NO NOVO UPDATE *ABRIL 2023* DO30 janeiro 2025 -

Sly Cooper: Thieves in Time Review (PS3)30 janeiro 2025

Sly Cooper: Thieves in Time Review (PS3)30 janeiro 2025 -

![Best Monster Hunter Rise Mods [2023 Ultimate List] - GamingScan](https://www.gamingscan.com/wp-content/uploads/2022/07/Best-Monster-Hunter-Rise-Mods.jpg) Best Monster Hunter Rise Mods [2023 Ultimate List] - GamingScan30 janeiro 2025

Best Monster Hunter Rise Mods [2023 Ultimate List] - GamingScan30 janeiro 2025 -

Watch Horimiya - Crunchyroll30 janeiro 2025

-

Nature Chart - Pokemon: Let's Go, Pikachu! Guide - IGN30 janeiro 2025

Nature Chart - Pokemon: Let's Go, Pikachu! Guide - IGN30 janeiro 2025